Global Machine Tools Industry PR Newswire

Mar 04, 2020· NEW YORK, March 4, 2020 /PRNewswire/ . Machine Tools market worldwide is projected to grow by US Billion, driven by a compounded growth of .

WhatsApp)

WhatsApp)

Mar 04, 2020· NEW YORK, March 4, 2020 /PRNewswire/ . Machine Tools market worldwide is projected to grow by US Billion, driven by a compounded growth of .

Used for stock removal and precision grinding, floor segments or surface preparation tools are grinding segments that are attached to a variety of floor grinders or floor machines. available in a variety of shapes and sizes, grits and segments to provide the exact finish required for your project.

Never used. Machine is still packed at the manufacturer place. Warranty from Lapmaster: 6 months. Homologation of machine carried out by Lapmaster Software included Grinding wheels: The wheels are from Diprotex (Grinding Wheel CBN105855 from Lapmaster M02). "dressing ring (0 / 1) 55t237h 19" The machine has an oil filtering unit and a grinding unit for grinding wheels and oil.

Mill Grinder Drill Bit Sharpener MRX3 Sharpening Grinding Machine 414mm 220V. Was: Previous Price 2 Steampunk Custom Made Vintage Machines Grinder Punch Drills DELTA ROCKWELL . 90Pcs Electric Grinder Grinding Suit Rechargeable For Carving Drilling Polishing.

Linkhood 4" Diamond Cup Grinding Wheel, 12Segment Turbo Row Concrete Grinding Wheel Disc Heavy Duty Tool for Angle Grinder, for Granite, Stone, Marble, Masonry, Concrete out of 5 stars 11 7 . 99

Jul 07, 2020· Machines (Product Segment) World Market Estimates and Forecasts by Region/Country in US Thousand: 2020 to 2027 Table 14: Grinding, Honing, Lapping, Polishing Buffing Machines (Product Segment ...

The Jowitt Molemab Partnership Jowitt is the sole importer for Molemab products in the UK. Molemab, the world''s 4th biggest bondedabrasive manufacturer produce a complimentary range of products including speciality vitrified and standard stock as well as resin, vitrified and metalbonded diamond and CBN products.

Grinding wheel segments are generally used to grind flat stock or flat surfaces within a workpiece for anything from heavy stock removal to precision grinding. Available in a variety of shapes, sizes and grain types to meet your job requirement.

Used for stock removal and precision grinding, floor segments or surface preparation tools are grinding segments that are attached to a variety of floor grinders or floor machines. available in a variety of shapes and sizes, grits and segments to .

Find the perfect grinding machine stock photo. Huge collection, amazing choice, 100+ million high quality, affordable RF and RM images. No need to register, buy now!

Segment Grinding . The key to successful segment grinding is twosided. First, the use of the correct specification for the job and second, the correct operating procedure. It is important to utilize a special segment bond formulation to allow for improved chip clearance, especially in heavy roughgrinding .

Cup grinding machine, swivel arm grinding machine, carbide chip breaker groove grinding machine, tool grinding machine, grinding machine, angle grinding machine, turning steel grinding machine clamping table 410 x 410 mm magnetic plate 470 x 160 mm Dobi7roh grinding wheel diameter 90 mm Dimensions 1440/760 / H1745 mm Weight 712 kg more

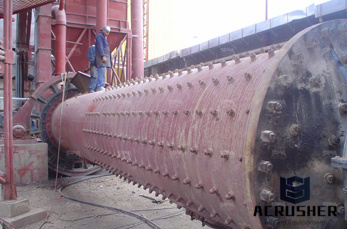

「segment grinding machine photo 」 Automatic grinding machine for radius segment Nov 14, 2016· MG21 Automatic radius grinding machine for diamond segment Shanghai Mountain Mechanical Equipment Co., Ltd / Kunshan Mountain Automation Equipment Co., Ltd. is a hightech enterprise . Learn More. Live Chat

Using our automatic bidding agent, you can define the maximum price you are willing to pay for the machine you are interested in. ... ZSE 40 Flat Segment Grinder . Xing LinkedIn Mail Facebook Twitter Do you have any questions? We are at your service: +49 (0)211 . 20. Years online. Registered buyers.

Nov 13, 2016· MG21 Automatic radius grinding machine for diamond segment Shanghai Mountain Mechanical Equipment Co., Ltd / Kunshan Mountain Automation Equipment Co., Ltd. is a hightech enterprise ...

Surface area, segment size, bond and grit are all extremely important. For fastest removal, minimum segments in the correct shape with matching bond are the most critical. Grit generally should be around #30#40 to achieve best results. Traditionally grinding wheels have been designed to focus entirely on grinding which limits their speed.

The standard machine for beginners and experts in the precision grinding segment Designed for workpieces smaller than Ø 400 mm x 1000 mm Between tips up to 100 kg, Flying up to 80 kg

Mar 07, 2020· Grinding Machines market worldwide is projected to grow by US1. 5 Billion, driven by a compounded growth of 4. 4%. Surface Grinding Machines, one of .

About 25% of these are grinding machines, 9% are other metal metallurgy machinery. A wide variety of grinding machine options are available to you, such as cnc, normal. You can also choose from surface grinding machine, internal grinding machine, and cylindrical grinding machine. There are 44 grinding machine suppliers, mainly located in Europe.

Nov 15, 2012· Grinding on a Swiss offers several advantages over milling. Grinding is a continuous cutting process, which can provide a better finish than milling''s interrupted cutting process, which induces vibration into the part being machined. Grinding processes operate at a much higher sfpm than milling.

Grinding machines 2839 new and used machines online Compare prices now!,HSS and segment circular saw blade chamfering machine (automatic) Businaro Polar ACM 650 1998 ready for operation (used),Efqi8i89 All parts shown on photo come with machine GfZoProof Bri fwaofuadclpbptze,

Homend High Speed 500g Electric Grain Mill Grinder Powder Machine Spice Herb Grinder 2500W 70300 Mesh 36000RPM Stainless Steel Commercial Grade for Kitchen Herb Spice Pepper Coffee (500g) by homend 63 . 95

In 2017, the overall grinding machines market worldwide was dominated by the cylindrical grinding machines segment. Cylindrical grinding machines are among the most popular grinders used across various applications such as machine tools parts manufacturing, automotive and others. In addition, due to high cost per unit, the segment revenue ...

As a standardized machine, the KELLENBERGER® 10 is able to deliver a priceperfomance ratio yet to be matched. Combining proven components now updated according to the latest technology, with an intuitive programming surface, it creates a very capable base easily customizable by a range of optional equipment to the needs of the customer.

WhatsApp)

WhatsApp)