In search of GOLD using the GOLDDRUM ~ Wet or Dry ~ Gold ...

Apr 08, 2012· When you want to clean out, just turn off the machine and scoop out the material with a plastic scoop and pan it... WET or DRY the golddrum is AWESOME and easy. Click on .

WhatsApp)

WhatsApp)

Apr 08, 2012· When you want to clean out, just turn off the machine and scoop out the material with a plastic scoop and pan it... WET or DRY the golddrum is AWESOME and easy. Click on .

FEECO has worked with everyone from startup companies, all the way to Fortune 100''s, including entrepreneurs, as well as some of the world''s top engineering firms.

construction and working of electric mixer ... Electric Cement Mixer 70 Litre 250W Portable Concrete Mortar Mixing Machine 240V ... ensengai palm oil mill ... Cement Mill, Cement Grinding Plant ... Cement Mill Crushing Mill. Cement mill is widely used in dry or wet grinding process of all kinds of ores ... small driving gear ...

Buy sell used construction equipment, trucks government surplus. Bid online, onsite, buy now or make an offer. Buy with confidence with our IronClad Assurance®.

typical flow sheet dry ball mill BINQ Mining. Dec 20, 2012· a typical flow sheet of iron ore beneficiation. This page is provide professional a typical flow sheet of iron ore beneficiation information .Ball mill coal grinding; .

To optimise the development of the pit and ensure that ores of consistent grade are sent to the processing plant, mining will take place at several levels and in assorted ore grades. The mine will have a :1 waste to ore stripping ratio. A trial mining project was carried out in December 2010 based on the Karara South and Karara East DSO ...

From Central Mix Plant and Concrete Batch Plant to Concrete Plant, you can buy and sell Concrete Plants at IronPlanet from any and all manufacturers, including Alkon, BMH, Ciber, Piccini and more. If you are looking for a Concrete Plants, check out our upcoming heavy equipment auctions to find used Concrete Plants for sale.

Main feed into a sinter plant is base mix, which consists of iron ore fines, coke fines and flux (limestone) fines. In addition to base mix, coke fines, flux fines, sinter fines, iron dust (collected from plant dedusting system ESP) and plant waste are mixed in proportion (by weight) in a rotary drum, often called mixing and nodulizing drum.

Producing wet and dry cake further increases this cost particularly if high throughputs are required. However, some of the many advantages to using dry stacking of tailings are: Can be used in areas where water conservation is critical and any water loses can jeopardise plant performance.

Aug 30, 2012· For example shale, fly ash, mill scale and bauxite. These raw materials are directly brought from other sources because of small requirements. Before transportation of raw materials to the cement plant, large size rocks are crushed into smaller size rocks with the help of crusher at quarry.

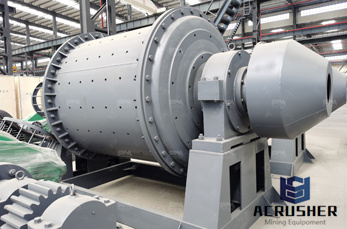

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

Mining (EHM) orebody The EHM orebody is an iron oxide copper gold (IOCG) deposit with magnetite being the form of iron ore. EHM''s Ore Reserve Estimate at 30 June 2010 is 88 million tonnes at a grade of 1% copper, grams per tonne gold and 23% magnetite. In 2010, EHM produced 74,595 tonnes of copper in concentrate and 91,259 ounces

Hands on the wheel: how the rapidly evolving auto industry is changing mining forever. While the auto industry has never stood still, the rise of electric vehicles and emergence of a new middle class in countries like India and China is changing the industry at a much faster pace than ever before, sending shockwaves through the mining world.

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill.

The chart/table below are crude budgetary estimations for the cost of major plant equipment. Actual cost will vary depending of the process details and detailed equipment list and origin. Please use this to decide if your project and dream for becoming a miner or mining company is something you can afford. This is only an approximation.

JXSC works on offering services for the mines and mineral processing plants, rting efficient and safe processing performance in the global mineral resources industry with our reliable mining equipment and innovative solutions. From its tough beginning, the business that started in 1985 went to win the trust both home and board, with mineral processing machines sold to over 100 countries ...

In municipal waste water treatment plants (MWWTP) the KS Paddle Sludge Dryer System produces Class A Biosolids in accordance with the EPA''s 503 regulations allowing the dried granular material to be used beneficially as a slow release fertilizer or soil amendment. Dried waste products have also been used as fuel in boilers and cement kilns.

Dry Grinding VS Wet Grinding. ... the grinding of the raw mix in a cement plant may be carried out either wet or dry but the grinding of the cement can, from the nature of the material, only be carried out dry. ... It is theoretically possible to introduce such substances in gaseous or vapour form into dry mill but, in practice, such methods ...

The topic of "energyefficient" treatment is central to the NETZSCH philosophy and policies for the Business Field "Minerals Mining". Whether ore, limestone, talc, graphite, cement or other basic commodities in the raw materials industry, our customers crush, classify and disperse efficiently with every run on NETZSCH production equipment.

Bleiwas,, 2011, Estimates of electricity requirements for the recovery of mineral commodities, with examples applied to subSaran Africa: Geological Survey OpenFile Report 2011–1253, 100 p.

Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from lowgrade iron ore requires a long process of mining, crushing,

Rotary scrubbers for iron ore beneficiation plants as well as granulating drums, pelletising discs and all kind of rotating equipment are also included in CEMTEC''s wide range of products. Wet and dry grinding tests. The parameters for each individual application can be verified in CEMTEC''s pilot test plant .

mixer / conditioner / unloader effectively transforms dry fly ash into uniformly wetted ash resulting in a completely controlled, efficient and dustfree operation with capacities ranging from 1 to 400 tons per hour. Larger units are available upon request.

Iron ore pelletizing systems. Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast furnace or DRI plant as part of the process to make steel.

WhatsApp)

WhatsApp)