(PDF) Energy survey of the coal based sponge iron industry

Jul 30, 2020· The actual process of the coal based sponge iron production is based on SL/RN proce ss (jointly developed by the S teel Company of Canada, L urgi .

WhatsApp)

WhatsApp)

Jul 30, 2020· The actual process of the coal based sponge iron production is based on SL/RN proce ss (jointly developed by the S teel Company of Canada, L urgi .

Boudouard reaction, dolomite, DRI, Iron ore, metallization, non coking coal, pellets, reduction, Rotary kiln, Sponge iron, Sulphur, Coal based Direct Reduction Rotary Kiln Process . The coal based direct reduction rotary kiln process was developed for converting iron ore directly into metallic iron without the melting of the materials.

Sep 01, 2015· The actual process of the coal based sponge iron production is based on SL/RN process (jointly developed by the Steel Company of Canada, Lurgi Chemie, Republic Steel Company and National Lead Corporation in 1964), which works on direct reduction of process is adopted by worldwide conventional sponge iron industries.

• Sponge iron produced by the process will be the high grade which contains 80% Fe, 12% FeO and 8% gangue material. After separation of sponge iron in the magnetic screen/pulley, the remains are collected as char. Char has good amount of fixed carbon (25% 30%) and moderate GCV (2500 .

Tunnel Kiln Process For Sponge Iron. A tunnel kiln process direct reduction of iron ore from tunnel kiln process dec 27 2017 dri tunnel kiln case group dridirect reducted iron tunnel kiln was commissioned on 24 november 2011 the process of tunnel kiln uses fines of iron ore and coal which are mixed together in the oxides of iron are reduced to iron as per the above reactions

India is the world''s largest producer of sponge iron, most of which is produced primarily through the coal based method of production. Growth in the sponge iron production can be attributed largely to the popularity of secondary steelmaking route, which has shown a phenomenal growth in India.

In India, the standard DRI processes are modified in a minor way and thereafter referred to as customized/indigenous technology. Only trivial changes in terms of the feed ratio, length and the diameter of the kiln are made in the name of customized technology. These customized technologies are dominating the coal based sponge iron process in India.

DRI is successfully manufactured through either gas or coalbased technology. Iron ore is reduced in solid state at c either by reducing gas (H2+CO) or coal. The direct reduction process uses palletized iron or natural ''lump'' ore. Process. Sponge iron making is a process in which iron ore lumps (typically 5mm18mm size) are tumbled ...

crusher in sponge iron process brief process of coal based sponge iron rotary kiln. Customers want and that is our goal we produce ore crusher( brief process of coal based sponge iron rotary kiln) mill crusher mobile crushing plant processing equipment according to the specific needs of our design and production lines fully the interests of customers.

Objective: A typical coal based sponge iron plant is investigated to utilized waste heat to preheat the feed coal and air as well as increase the productivity of sponge iron by applying heat integration using simulation process. Methods: In the present work, utilized waste heat to preheat the feed coal and air, heat integration process using modified pinch approach is applied and to increase ...

Coalbased sponge iron process The process of the direct reduction of haematite in a rotary kiln is schematically described in the Fig. 1. Haematite and noncoking coal are fed to the kiln at controlled rates without premixing and the charge moves through the kiln depending upon the rotation

SPONGE IRON PLANT. MANUFACTURING PROCESS Coal based Direct reduction process is classified based on the reducing agent namely solid. Most solid reduction process use noncoking coal as reducing agent due to abundantly available noncoking coal. The process proposed to be adopted is the rotary kiln proposes using Noncoking coal and iron ore.

This process is one of the oldest direct reduction methods and the idea of its structure is based on a horizontal cement kiln. In this method, heat coal (as a reducing agent) is mixed with iron ore and sponge iron is produced in a horizontal furnace.

Iron Sponge Process

Sponge Iron Production Process. Market share: About 23% of sponge iron total production 4) Tunnel furnace process This process is the oldest direct reduction method In this method, Thermal coal is mixed with iron ore as a reducing agent Natural gas generates the required reduction temperature, and reduction is performed on Silicon Carbide (SiC) Crucibles in a tunnel furnace...

Oct 25, 2013· Coal gasificationbased sponge iron plant of Jindal Steel Power Ltd in Angul, Odisha, may become a game changer in the coming years. This plant is likely to be commissioned in 2013. Cost of syn gas and efficient running of gasifiers will be the key of success of this promising sponge iron process .

The process of sponge iron making aims to remove the oxygen from iron ore. The quality of sponge iron is primarily ascertained by the percentage of metallization (removal of oxygen), which is the ratio of metallic iron to the total iron present in the product. ... SL/RN technology is a coal based rotary kiln direct reduction process : Process ...

who make sponge iron from coal and iron ore process. Abstract Today India stands as the largest producer of coal based sponge iron through rotary kiln process using calibrated ore and non coking coal However Rotary kiln process suffers from serious limitations like low productivity and pollution In this respect fixed bed Tunnel kiln furnace are evolving as an alternative to Rotary kiln process

Directreduced iron (DRI), also called sponge iron is produced from direct reduction of iron (in the form of lump, pellets or fines) by a reducing gases produced from natural gas or coal. This reduction takes place in the temperature range 800 1050 degrees C when reducing gases; mainly Hydrogen and Carbonmonoxide; react with the iron oxides ...

Amba Shakti Group is one of the most creditable steel companies of India.

Make Sponge Iron From Coal And Iron Ore Process. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

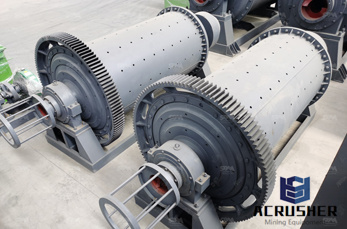

Manufacturer of Coal Gas based DRI Plant Rotary Kiln for Making Sponge Iron, Sponge Iron Plant, Gas Based HYL DRI Plant and Coal Based DRI Plant offered by Remso Control Technologies Private Limited, Greater Noida, Uttar Pradesh.

Brief description of sponge iron plant process. 40. Technological options for coal based plants. 42. Status of Sponge Iron Plants in India. Get Price; Iron and Steel Indian Bureau of Mines. sponge iron also referred to as Direct reduced iron (DRI), based both on coal and gas as well as to (a) Coalbased Rotary Kiln Krupp ...

Sponge iron produced using the non coking coal is called coal based sponge iron / DRI. For producing the sponge iron through this process requires high grade of iron ore and non coking coal. Gas Based DRI / HBI. In this process route, iron oxides are converted to the DRI / HBI by using natural gas in a vertical shaft furnace. ...

WhatsApp)

WhatsApp)