Ball and Pebble Mills | Bid on Equipment

Save money on our extensive inventory of Used Ball and Pebble Mills at Bid on Equipment. New Inventory added daily!

WhatsApp)

WhatsApp)

Save money on our extensive inventory of Used Ball and Pebble Mills at Bid on Equipment. New Inventory added daily!

Ball and pebble mills. 7ft x 12ft grinding mill,addition of pebbles to a ball,aluminium pebble for ball mill,ball and pebble mills,ball and pebble mills theory,ball mill horizontal for ore,ball mill operating principles, components, uses,ball pebble mills, ball mill machine,drais mill ball pebble pml vh for sale 5b9904,effect of pebble vs balls in a ball mill,

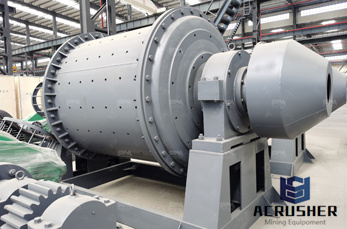

Pebble mills are a type of ball mill and are also used to reduce the size of hard materials, down to 1 micron or less. Because of their fairly simple design, ball mills and pebble mills are less likely to need costly repairs (unlike other crushing or extraction equipment) making them an attractive option for businesses on a budget.

Media, balls or cylinders are used inside the containers to grind, disperse, impact, mix and mill the material to be processed. Ball Mills, generally unlined, steel mills and Pebble Mills, generally lined mills of porcelain, rubber, plastic, etc. are larger versions of these apparatus.

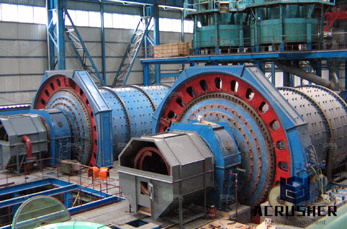

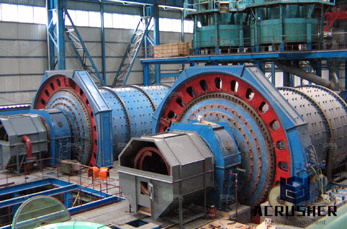

The Continuous Ball and Pebble Mill grinding units range from 24 610 mm diameter to 96 2438 mm diameter and from 36 915 mm long to 360 11 m long PATTERSONs unmatched Ball and Pebble Mill custom design experience and manufacturing capability is your assurance of a system that meets your requirement for maximum grinding efficiency at a ...

The second primary function of a liner is to transfer rotary motion of the mill to the grinding media used in ball mills, to a ball mill than to remove. Patterson Industries – Ball Pebble Mills. Grinding Media: PATTERSON Mills may be charged with Flint Pebbles, Liquid Discharge Lids and grinding door covers for Ball Mills.

Steel Ball and Pebble Mills Stevenson Manufacturing Company . Steel Ball and Pebble Mills. Steveco manufactures a complete line of Steel ball and Pebble mills for every wet or dry grinding process for size reduction and for ...

Ball and pebble mills theory mayukhportfoliocoin theory and practice for jar, ball and pebble milling us stoneware jar, ball and pebble milling theory and practice operating division of er advanced ceramics, inc 700 east clark st po box 270 east palestine, ohiochat online laboratory ball .

Liquid Discharge Lids and grinding door covers for Ball Mills. PATTERSON® Urethane Lined Pebble Mill Door for 6''0" dia. PATTERSON® Pebble Mill – Top Side As above Bottom Side 18" Babitted Replacement Bearings for PATTERSON® Ball Mill.

Welcome to the premier industrial source for Mills: Ball Pebble. The companies featured in the following listing offer a comprehensive range of Mills: Ball Pebble, as well as a variety of related products and services. provides numerous search tools, including location, certification and keyword filters, to help you refine your results.

Find out all of the information about the Corporation product: ball mill / horizontal / for ore Ball/Pebble Mills. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale.

In pebble and ball mills quite often charge volumes close to 50 % are used. In a pebble mill the pebble consumption ranges from 3—15 % and the charge has to be controlled automatically to maintain uniform power consumption. The volumetric density of a rod and a ball charge is around ton/m³ (310 lb/) corresponding to 37 % void space. ...

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applications. Some of those applications are grate discharge, peripheral discharge, dry grinding, special length to diameter ratio, high temperature milling oprations and more.

Jars, Ball, Pebble Mills Vibratory Type Mills. Aadvanced Machinery offers a wide selection of attritors and paint mills used for particle size reduction, dispersion and particle size grinding and milling.

Ball Mills, Pebble Mills, Material Processing Mills: For more than a century, Patterson has been the industry leading manufacturer of wet and dry grinding mills for size reduction or dispersal. Patterson''s ball, pebble and rod mills are built to last. We are still filling parts requests for mills sold over 60 years ago. Patterson mills are available in a wide variety of standard sizes and ...

Federal Equipment Company also offers used ball and pebble jar mills with various capacities and linings, so you can find one that works for your manufacturing needs. By purchasing your used ball mill or pebble mill from Federal Equipment Company, you will be purchasing from a trusted name in processing equipment.

Ball and pebble mills are suspended on structural sieel frames beneath the decking with access from above thiough letuovable sections of flooring. Working. THE APPLICATION OF PEBBLE OR BALL MILLS IN ENAMELING THE APPLICATION OF PEBBLE OR BALL MILLS IN ENAMELING (pages 853857)A description of pebble mills in enameling is given details of design ...

Types TD and TDJ Ball and Pebble Mills. For certain applications, PATTERSON recommend the simplicity, compactness and low maintenance features of these mills. Ring gears and pinions have been replaced by a torque arm drive. The construction of cylinders is the same as other PATTERSON Mills, but sizes are limited in steel ball models to 3''6" x 4 ...

Handbook of ball and pebble mill operation Ball mill and pebble mill operation Ball and pebble mill operation: Reviews. Usercontributed reviews. Tags. Add tags for "Handbook of ball mill and pebble mill operation.". Be the first. Similar Items. Related Subjects: (6) Ball mills Handbooks, manuals, etc. ...

n A rotating mill for reducing size of materials (, pigments and fillers) or pulverize them using hard metal or ceramic balls. (Perry RH, Green DW (1997) Perry''s chemical engineer''s handbook, 7th edn. McGrawHill, New York).

offers flexible autogenous (AG) mills, semiautogenous (SAG) mills, ball and pebble mills, as well as stirred mills to fit your needs. Wide offering. Grinding mills, spare and wear parts as well as maintenance and optimization services. Efficiency through automatized operation.

Arnold Equipment maintains a great selection of industrial ball, pebble, and rod mills. Our personallysourced grinding mills can provide superior impact and attrition to produce the finest powders. We have, or can locate, the equipment you need. Our used ball and pebble mills are available in various capacities and linings, with the capability to grind highly abrasive and toxic materials. We ...

WhatsApp)

WhatsApp)