improve ball mill efficiency

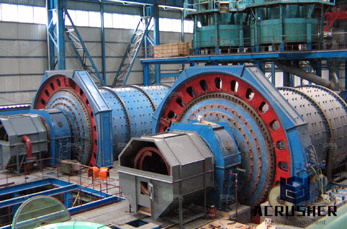

Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two.

WhatsApp)

WhatsApp)

Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two.

5 Ways To Improve Grinding Efficiency Of Ball Mills News Dec 26, 2017 Several factors affect the efficiency of a ball mill for cement grinding. In this article, we shall be looking at some of these factors that have been proven to influence grinding efficiency: Mill Geometry And Speed According to Bond (1954), the grinding efficiency of a mill ...

Improve Cement Ball Mill Productivity. Our company mainly producing and selling machines like jaw crusher, ball mill, sand maker, sand washing machine, mobile crushing plant, Improve Cement Ball Mill rock industries nigeria plc ebonyi state Establishing a special research and development base and taking technological innovation as our main duty help us always taking the ...

When the proportion of pebbles in the mill charge was low (up to 30%), the larger pebbles wore away significantly faster than expected, based on a constant surface wear rate. This could be due to size segregation in the mill. CITATION. Nkwanyana S and Loveday B. Addition of pebbles to a ballmill to improve grinding efficiency.

Apr 24, 2019· Ball Mill: How to work in Beneficiation/ Dressing Data shows, the cost of ball mill in the mineral(like gold/iron/silver and so on) beneficiation account for 50%.

How to improve the grinding efficiency of the ball mill. The grinding efficiency of ball mill is low, the treatment capacity is low, the production energy consumption is high, the product fineness is unstable and so on, which are the problems that most concentrators will encounter.

Increase ball mill efficiency ontwerpbureau . Increase ball mill efficiency. The grinding efficiency of ball mill is low the treatment capacity is low the production energy consumption is high the product fineness is unstable and so on which are the problems that most concentrators will encounter How to effectively improve the grinding efficiency of ball mill is an important problem In this ...

Dec 26, 2017· Several factors affect the efficiency of a ball mill for cement grinding. In this article, we shall be looking at some of these factors that have been proven to influence grinding efficiency: Mill Geometry And Speed. According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed.

5 Ways To Improve Grinding Efficiency Of Ball Mills – According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed. Ball mills with different length to diameter ratios for a particular power rating will .

Apr 01, 2017· Table 3 is a summary of the preliminary tests (in duplicate) using various proportions of balls and pebbles. The online torque measurement was used for early measurement of the power drawn by the mill, so that the grinding time could be calculated, to maintain the same amount of energy for all tests ( assuming a constant grinding efficiency).

Therefore, large feeding sizes will affect ball mill efficiency. 3. Mineral slurry density: in wet grinding, material pass time, production efficiency and ball mill power are all influenced by mineral slurry density. Generally speaking, the suitable density is close to 80% when feeding size .

A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns). The required product size distribution is to be 80% passing 100 mesh (149 microns).How to Improve the Output of Cement Ball Mill Zhongde Cement ball mill grinds cement by dry grinding.

Improve ball mill grinding fineness we can do to improve the ball mills fineness the ball mills operation is mainly based on the parameter goal of cyclic load portable water well drilling rigs for sale, powderselecting efficiency, together with the reasonable collocation of wind, material and fineness to control the grinding ...

wed how to increase the efficiency of a ball mill. Efficiency increase in ball mill veronaschoolhouse. High Efficiency Cement Mill,Crusher,Packing,Silo,Separator Manufacturer With Ce,Iso Approved, Find Complete Details about High Efficiency Cement Mill,Crusher When working for raw mill, powder concentrator could increase the output by 3040%, and help with the stability of grain ...

As one of the commonly used mineral processing equipment, the quantity and proportion of steel balls in ball mill barrel not only affect the grinding efficiency and production capacity of ball mill, but also affect the ball mill''s service life.. In the operation process, grinding efficiency of ball mill generally depends on the sum of the work done by each steel ball (the number of steel ...

Mar 08, 2013· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill. in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%]. please expalin in a n excel sheet to calcualte the same. thanks. sidhant. reply

Addition of pebbles to a ballmill to improve grinding. Further tests were done, using samples from a platinum mine, namely the feed to a secondary mill (ballmill) and rounded pebbles from a primary AG mill Grinding capacity was maintained over the range 0–30% pebbles, by volume, with savings in energy and ball consumption increasing progressively.

How to Improve Ball Mill Grinding. It also presents an excellent means of strategizing circuit improvements to increase production rate, for example, by increasing energy input (the mill power draw); by adjusting the classification system performance through pump and cyclone modifications; or, by improving the efficiency of the grinding mill

Improve Ball Mill Efficiency Abstract. ball mill working principle:improve 20% grinding · Ball Mill: How to work in Beneficiation https:// Data shows, the cost of ball mill in the beneficiatioAnalysis of Ways to Increase Ball Mill Efficiency There are kinds of ball mills according to their different functions such as dry type mill, wet type mill, grid ball mill and overflow ball mill.

Jan 11, 2020· The optimized grinding media can improve the ball mill efficiency by about 30%. Lining Plates. The lining plate is another part that direct contact with the material. The liner made of ordinary material is too thick, which will reduce the effective volume of the ball mill cylinder. Besides, thick liners increase power consumption due to the ...

Factors Affecting Ball Mill Grinding Efficiency. The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this ...

Choose right speed to improve ball mill grinding efficiency Date: 19:36:39. Ball mill is one of the commonly used equipment in mineral processing equipment. Rotation speed is one of the main parameters in the design and operation of the ball mill. The rotation speed directly determines the movement state of the grinding medium in the ...

Enhance the barrel volume can improve the ball mill working efficiency. Ordinary alloy liner plate has thick thickness and large weight, which reduces the ball mill volume and increase the power consumption, lower the working efficiency. Therefore, the liner plate quality is very important, ZGMn13 liner plate is the suitable choice.

Ball mill circuit classification system performance is considered here first because it provides the basis for subsequent characterization of ball mill breakage efficiency. Major design and operating variables in closed circuit ball milling of a specified feed to a desired product size are summarized in Table 1.

WhatsApp)

WhatsApp)