Cement Mill Soft Start Electric motors generators ...

Feb 12, 2009· RE: Cement Mill Soft Start Compositepro (Chemical) 12 Feb 09 12:25 It may also work to reverse the mill by one quarter turn to get the ball load to .

WhatsApp)

WhatsApp)

Feb 12, 2009· RE: Cement Mill Soft Start Compositepro (Chemical) 12 Feb 09 12:25 It may also work to reverse the mill by one quarter turn to get the ball load to .

Mills grinding raw materials to very fine grain are used at various stages in cement production. Due to their low energy consumption in comparison with conventional horizontal mills, it is preferable to use vertical mills that employ enormous drives. Its energy efficiency and its performance depend to a large extent on the drive system.

Feb 10, 2016· VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 – TPH) and before implementing the project, we would like to

May 13, 2018· Soft starter motor with mill 100 HP Duration: 0:43. The Conductance 2,665 views. 0:43. Starting a 6kV 3Ph 2,200 kW 1,000 rpm slipring motor for a cement ball mill Duration: 3:51.

Vertical roller mill Homogenization silo Fine grinding performed by vertical mills Mills grinding raw materials to very fine grain are used at various stages in cement production. Due to their low energy consumption in comparison with conventional horizontal mills, it is preferable to use vertical mills that employ enormous drives.

jaw crusher introduction use in cement plant. Cement Production Line in Cement Plant · Cement mill is key equipment during the process of producing cement in cement making plant, and is used for grinding the crude material, clinker, coal powder, calcium lime and other mixing materials.

Apr 17, 2020· Thailand: Siam Cement has ordered a LM +3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi. The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestone. The cement producer previously ordered a LM +3 CS mill from Loesche for its Ta Luang cement plant in 2014.

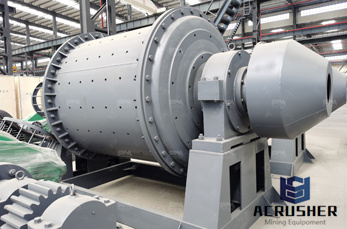

• Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants. In this paper authors are covering the process diagnostic study of Ball mill for cement grinding. 2.

Gearbox Repair. All Industries utilize gearboxes in a variety of applications. Some industries, such as Plastics, power generation, distillation, cement and aggregate, paper mills, and the petrochemical industry, require hightorque gearboxes, which can provide continuous as well as noisefree performance.

Soft starters offers a wide range of benefits for mining, aggregate and cement applications. Features such as undercurrent/overload monitoring and instantaneous over current protection can significantly reduce costly downtime and repairs to motors and motordriven equipment. They also reduce current start stress on the electrical supply.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Oct 18, 2016· Starting a 6kV 3Ph 2,200 kW 1,000 rpm slipring motor for a cement ball mill Duration: 3:51. Yves Mamin 526,972 views

Grinding mill parts India,South Africa,Philippines and ... Ball Mill for Cement Plant in IndiaThe proposed clinkerisation plant is ...mill system consists of a Vertical roller mill to grind 1250 tph to ...

CEM Drive System intelligence for vertical mills. for vertical mills WE DISCOVER POTENTIAL. Ingenious Soft startup of the mill Since introducing with great success in 1966 the technology of mill gear units to the cement industry we have sold over 6000 MAAG™ gear units and 1000 girth gears.

for vertical mills WE DISCOVER POTENTIAL. Ingenious ... Soft startup of the mill ... Since introducing with great success in 1966 the technology of mill gear units to the cement industry we have sold over 6000 MAAG™ gear units and 1000 girth gears. In todays'' setup, Engineering and ...

Cement mill production system of inverter can achieve the following objectives: Drive motor soft start. 5000 t/d production line: about 3800 kw, cement raw meal grinding motor 2 * 3550 kw grinding motor; Its startup inrush current can reach more than 12 times of the rated current, direct can lead to .

The stacker and reclaimer is the prehomogenization system in the cement a necessary part of the cement production line, it can concurrently or respectively complete the stacking and reclaiming. The stacker and reclaimer plays a vital role in the limestone prehomogenization, stabilize the condition of cement kiln, ensure the clinker quality.

These cookies collect information that is used either in aggregate form to help us understand how our website is being used or how effective our marketing campaigns are, or to help us customize our website and application for you in order to enhance your experience.

It is excellent solution slow start, soft stop and less starting current. Manufacturers of soft starters generally recommend using it for different pumps and fans. Can we use of soft starters (instead of the classic star/delta start) for starting heavy mills for stone, plastic or cereals (power up to 200 KW at 400 V, speed 1400 or 2900 rpm?

Intelligent and Adaptive Soft Starters. The WorldStart IQ line of soft starters features the intelligent motor control technique, Adaptive Control. During starting and stopping processes, Adaptive Control allows the soft starter to compare the motor''s estimated speed with the selected profile, automatically adapting to varying loads.

Liquid rheostat starter for ball mill autobedrijfdegrootiquid starters ball mills lajpatnagarco b series deep rotor vertical shaft what is liquid resistance starter ball mills mining and cement this page is about liquid get more infoement mill liquid starter 3n51 22 08 03 gefdcet a priceiquid resistant starters on ball mills.

Areas of Soft Starter application. These are main applications of Soft starter: Steel industries (Rolling mills and processing lines) Cement industries Sugar plants Paper and pulp Rubber and plastic Textile industries Machine tool applications Power sector Water .

We have Polysius Raw Mills Of Cement Mill Ppt,Polysius raw mills of cement mill ppt mayukhportfolio co polysius raw mills of cement mill ppt. polysius raw mills of cement mill price of clinker press roller for cement mill in chinenan mining polysius roller polysius vertical roller mill . inquire now crusher polysius mobilecrushing amp screening equipment

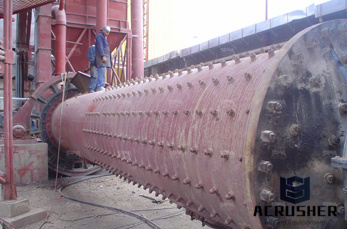

Starting electric motors for mills is the application mainly used with liquid rheostats. It takes a lot of starting torque for spinning large and heavy cylinders. Liquid rheostat Arecheta gets a soft start much better than any other engine starting system. Contact us for more information para starter cement mill.

WhatsApp)

WhatsApp)