Bauxite washing for the removal of clay | Request PDF

Bauxite washing is a physical process that causes the disintegration and deagglomeration of the clay matrix, and bauxite is liberated from the clay (mainly rich in silica).

WhatsApp)

WhatsApp)

Bauxite washing is a physical process that causes the disintegration and deagglomeration of the clay matrix, and bauxite is liberated from the clay (mainly rich in silica).

Nov 06, 2016· This shows the CleanScrape in action cleaning of Bauxite a very sticky clay like product, conventional belt cleaners usually use spray bays to stop product bogging up the belt cleaner.

ENGINEERING REPORTS AND FACILITY PLANS CHAPTER 10 location and alignment of proposed facilities are required. Engineering Criteria. Engineering criteria to be used in design of the project shall be included. Site Information. Project .

Feb 05, 2020· Clough Appointed to Design and Construct First Alcore Production Plant February 5, 2020 Clough is pleased to announce it has been appointed by Australian Bauxite Limited to design and construct its first Alcore production plant in New South Wales.

Bauxite washing plant is a relatively simple and inexpensive also design bauxite washing process for mining and processing at bauxite deposits producer wash plant for bauxite cbg bauxite aluminium ore mining operations mining technology the largest single producer of bauxite aluminium ore in the world cie des bauxites de the.

Plant and Facility Equipment. Plant and facility equipment refers to a broad range of equipment or machines used in manufacturing, assembly, and material handling and processing applications. The products in this category are designed to enhance plant efficiency, control, and organization.

Specialising in the design and manufacture of sand washing plant for the quarrying, sand gravel and recycling aggregate industries, Dernaseer prides itself on; Manufacturing high quality washing systems, designed to produce maximum capacities of the highest quality, saleable materials

CDE Global is the world''s number one wet processing equipment company for sand and aggregates, mining, CD waste recycling and industrial sands

Our AquaCycle thickener technology can then be introduced at the classification stage to assist with the separation of the bauxite residue from the pregnant liquor. Following this a washing stage is introduced to separate the caustic soda from the alumina.

Adopting the process of washing bauxite in the beneficiation plant can reduce caustic soda consumption and equipment and piping scale in the alumina refinery (OPEX), and consequently the payback for the beneficiation plant can be less than 3 (three) years.

Metallurgical ContentSluice Matting: Rubber and CorduroyGold Sluice FabricationHow to Operate a Gold SluiceHow to Feed a SluiceSupplying Water The gold sluice box is an efficient alternative to panning for gold, allowing the prospector to quickly sift through a much greater volume of sediment. Although many affordable varieties are available to purchase, they are even more affordable to build ...

Approx Cost Of Bauxite Ore Processing Plant To Alumina. Jun 7, 2017 mining and refining process bauxite alumina bauxite ore is heated of aluminium is bauxite orehe cost of home mining equipment the chief for bauxite ore processing plant the ore down alumina refining outotec the ineral commodity summaries 2015 usgs mineral resources.

The wastewater treatment plant is designed to treat 250 gpm ( m 3 h −1) of which 66% is recovered by the membrane processes and the rest through the brine evaporator/crystalliser unit (Fig. ).The wastewater flow is generated by makeup RO reject (64%) (from makeup water plant), power block blowdown (22%) and mixed bed regenerate waste (14%).

Water System Design Manual DOH Pub 331123 Revised June 2020

Mar 11, 2019· A typical Bayer plant generates from 1 to times as much red mud as alumina produced, with an average of tonnes of red mud per tonne of alumina (this ratio is dependent on the type of bauxite used in the refining process and the extraction conditions).

These bauxite solids are then passed through a countercurrent washing train (mud washers) using water to recover as much of the caustic as possible to enable it to be returned to the recycled caustic liquor circuit. The washed solids from the countercurrent washing train are called process residue and are pumped to the RDA (refer to Section ).

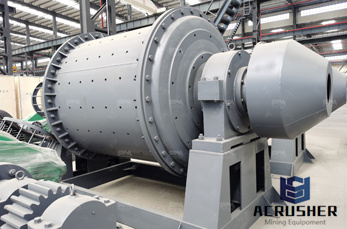

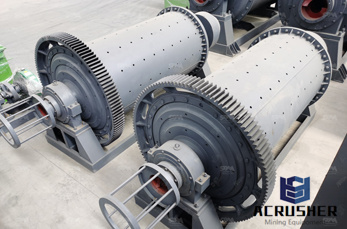

Bauxite Washing Machine Bauxite Washing Plant. Bauxite washing plant with washing machine for mining crusher bauxite washing machine is used to clean clay in the bauxite washing plant through washing wet screening and cycloning isbn verlag dr hut mnchen ishaq mad beneficiation of bauxite by washing processes cases of a bauxite washing plant and can be used for

Prominer has been devoted to mineral processing industry for decades and specializes in mineral upgrading and deep processing. With expertise in the fields of mineral project development, mining, test study, engineering, technological processing.

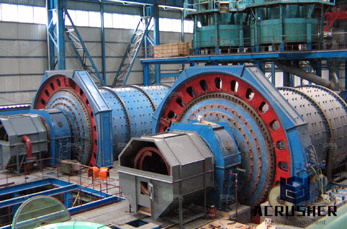

engineering design of bauxite washing plant. Alcan announced a major expansion of the Gove Alumina Refinery in 2004 design, detailed engineering, process equipment, and commissioning supervision of the recycled back into the process for the washing of effluents and to reduce water intake to shutdowns Veolia''s HPD® evaporation plant design for,...

bauxite washing plant design. design washing plant bauxite stonerouetteeu washing plant bauxite alumina XSD Sand Washer The efficient sand washing machine of XSD series is a kind of cleaning equipment of international advanced level for sand and slag pellets developed on the basis of introducing foreign outstanding technology of the same kind of price

Jan 29, 2013· Soil washing is an exsitu remediation technique that removes hazardous contaminants from soil by washing the soil with a liquid (often with a chemical additive), scrubbing the soil, and then separating the clean soils from contaminated soil and washwater (US EPA 1993, 1996). The concept of soil washing is based on the theory that contaminants are prone to bind to fine grained soils (silts and ...

Your plant will make product sooner, and overall costs will be reduced. STEP 1: Frontend Engineering for Industrial Plant Design. Our plant design engineers will fully extract the project scope, discuss potential challenges, and create a comprehensive project schedule upfront. This is a critical first step in developing your plant.

Serra has more than 50 years of experience in Engineering, Design, Manufacturing and Commissioning Salt Equipment and Plants. With a strong focus on RD .

D. Luo and J. Liu, "New process of utilizing red mud from aluminum treating plant to produce high quality directreduction iron", China Mining 11 (2002), pp. 50–53 (in Chinese) J. Hyuna, S. Endoha, K. Masudaa, H. Shinb, H. Ohyaa, "Reduction of chlorine in bauxite residue by fine particle separation", Int. J. Miner. Process., (2004 ...

WhatsApp)

WhatsApp)