Listings in Flowmeters, rotameters and Mills, ball ...

Listings in Flowmeters, rotameters and Mills, ball

WhatsApp)

WhatsApp)

Listings in Flowmeters, rotameters and Mills, ball

The average particle is subjected to an action similar to many sets of rolls in series, before it is discharged. Because of this, the rod mill can effectively reduce 1″ feed size to 10 mesh or finer in open circuit. The voids (or interstitial space) within a rod load are approximately half those in a ball mill .

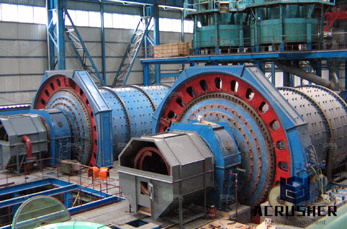

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary ...

Common uses for ball mills include machining both round bottom holes and complex contoured surfaces. Our carbide offering includes 2, 3, 4 flute ball mills. Lower flute counts are more efficient at removing material whereas higher flute counts create a smoother finish. All general purpose ball mills have a 30° Helix.

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

Mar 10, 2020· If a ball mill fails to reach critical speed, the balls will remain stationary at the bottom where they have little or no impact on the material. Ball Mills vs Traditional Milling Machines. Ball mills differ from traditional milling machines in several ways. First, ball mills don''t have a cutting tool. While traditional milling machines rely ...

Type "D" Ball and Pebble Mills. One of the most popular designs, the Type D mill is available as a steel ball mill with or without steel plate wearliners, or as a lined ball or pebble mill utilizing Alumina, Buhrstone or rubber linings. Type D ball and pebble mills are available in a variety of standard sizes from 15 inch to 8 foot diameters.

The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times. The PM 200 is a convenient bench top model with 2 grinding stations. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination ...

With more than 100 years of experience in ball mill technology, ''s ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

The ball mill lays a heatresistant soft rubber mat between the inner surface of the ball mill drum and the liner. To prevent the soft rubber mat from overheating, a 1015 mm thick industrial felt is placed between the ball mill liner and the soft rubber mat. The ball mill can Reduce the ball mill noise below the allowable standard.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were compared. It was concluded that vertical roller mill circuit has an advantage over ...

Cylindrical Ball Mill is an efficient tool for grinding materials like ores, chemicals, ceramic raw materials, paints etc. into fine powder or fine paste by grinding in a wet way. The Ball Mill operates by rotating a cylinder with grinding balls like steel, CI, ceramic and pebble balls as grinding media.

Inventory ID: 6CHM01. 3 Units UNUSED FL 26'' x 43'' Dual Pinion Ball Mill with 2 ABB 9,000 kW (12,069 HP) Motors w/ ABB VFD for Total Power of 18,000 kW (24,138 HP)

The working principle of ball mill and rod mill machine is similar, too. That is, the cylinder drives the movement of the grinding medium (lifting the grinding medium to a certain height then dropping). Under the action of centrifugal force and friction, the material is impacted and ground to required size, so as to realize the operation of ...

Also known as taper degree end mills, these end mills are angled from anywhere between 1/2° and 45° for machining angled slots in dies and molds. Ball End Mill Sets Good for rounded slots, sloping cuts, and contours, ball end mills have a rounded cutting edge.

The overall design of ball mills and rod mills are compact, with simple operation and easy maintenance. But the both are different in performance and applications. In this article, the similarities and differences between ball mills and rod mills are analyzed from 9 aspects, and suggest how to choose ball mill or rod mill.

Similar Ball Mills. View All 7 Ball Mills. Unused Patterson Ball Mill; 5'' Diameter X 6'' Lon. UsedMPT Ball Mill, Type MPT 300. 117" (3000 mm) d. Used Paul O. Abbe 50" x 135" Jacketed Rotary Ball. Used Stoneware Ceramic Ball Mill, 52 Gallon. Used Norton Chemical Process Products Jar Mill, A.

ball mills, but also from our comprehensive scope of services, ranging from maintenance and OEM spares procurement to the ... Singlecompartment mills are of a similar design to airswept mills, but the material is discharged mechanically by a discharge diaphragm. These mills .

Working Principle Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the ...

Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Ball mill in North American Market Ball mill is used everywhere and any industry .but in the north American ball mill is one type of the best guide for the market. if you don''t know how then please visit here present the information about the Ball mill in North American Market. | PowerPoint PPT presentation | free to view

Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill. To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at to

Like ball mills, grinding (steel) balls or pebbles are often added to stirred mills to help grind ore, however these mills contain a large screw mounted vertically to lift and grind material. In tower mills, there is no cascading action as in standard grinding mills. Stirred mills are also common for mixing quicklime (CaO) into a lime slurry.

WhatsApp)

WhatsApp)