principle operation of ball mill machine

Principle Operation Of Ball Mill Machine Principle of overflow ball mill the main component is a cylinder with diameter and length at a reasonable proportioniven by the transmission device the .

WhatsApp)

WhatsApp)

Principle Operation Of Ball Mill Machine Principle of overflow ball mill the main component is a cylinder with diameter and length at a reasonable proportioniven by the transmission device the .

ball mill operation and principle. HighEnergy Milling Springer. The principles of most frequently mills applied in highenergy milling are shown in Fig. .... balls, similar to the operation of conventional ball mills, but without the... The working principle and features of ball mill.

Several types of ball mills exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball mills.

Ball mill principle wikipedia delstbe. A ball mill works on the pri ball mill operation and principle academiae Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for .

May 22 2019nbsp018332the ball mill consists of a metal cylinder and a ball the working principle is that when the cylinder is rotated the grinding body ball and the object to be polished material installed in .

Pulverized Coal Machine Complete Production Line, Pulverized coal burner china henan zhengzhou pulverized coal burner is the key equipment of calcination system in metallurgical chemical cement quicklime rotary kiln its performance and operation relate to product quality capacity energy consump Pulverized Pulverized Coal Mill Operation Principle

Principle Of Ball Miller Machine Operation. Principle Of Working Of Cone Crusher Pol Principles of a gold shaker ball mill principles of a gold shaker ball mill according to its fineness and working principles,we divide coal mill well known planetary ball mill,the shaker mill or ...

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation .

Ball mill operation and principle principle operation of ball mill machine stone . ball mill wikipedia. a ball mill is a type of grinder used to grind and blend materials for use in mineral .

Jul 14, 2020· Ball mill, Grinding machine, Wet ball mill, Dry ball mill, Milling machine ... Hosokawa Alpine Ball Mill and Classifier | Principle of Operation Computer Animation Duration: 1:43.

An underloaded mill will have suboptimal milling performance and accelerated media wear. Scale Up Experimentation on a small laboratory scale jar rolling mill is possible as long as scaleup is considered. Ball milling is one of the few unit operation that improves with increasing mill diameter.

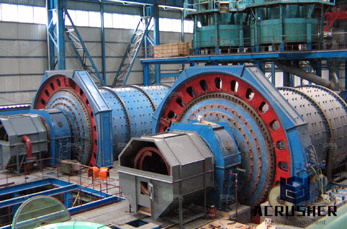

Operation principle. The ball mill is a cylindrical drum (or cylindrical conical) turning around its horizontal axis. It is partially filled with grinding bodies: cast iron or steel balls, or even flint (silica) or porcelain bearings. Spaces between balls or bearings are occupied by the load to be milled.

Principle of Operation, Maintenance and Function. Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills.

principle of ball mill operation. principle of ball mill loof amsterdamnl A Comparison of Three Mill Modes in Operating Principle A ball mill is a typical grinder and cylindrical device used in grinding or mixing materials such as chemicals, ceramic raw materials and paints The principle of ball mill function is.

ball mill principle of operation grinding mill china. Ball mill Wikipedia. A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser works on the principle .

Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding. Improving the competences of the team plays .

ball mill operating principle and maintenance,ball mill operation. 1 In the event you drive, check the good mechanical and electrical parts, check all connecting bolts loosing; each lubrication point .

Principle Operation Of Ball Mill Machine. Principle of overflow ball mill the main component is a cylinder with diameter and length at a reasonable proportioniven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in.

Ball Mill Operation Principle Picture Of Mining Machinery; Ball mill Wikipedia. The ball mill can grind various ores and other materials either wet or dry. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material. Many types of grinding media are suitable for use in a ball mill, each material ...

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

ball mill principle of operation. Get Price And Support. Cell Lysis and Disruption. Cell disruption Laboratory . ... The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory .

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed ...

Working Principle Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the ...

WhatsApp)

WhatsApp)