(PDF) Understanding the effects of liner wear on SAG mill ...

The SAG mill disch arges onto a trommel, the coarse material from the . ... The pebble stockpile material is fed to one or both of the cone crushers which discharge onto the SAG feed .

WhatsApp)

WhatsApp)

The SAG mill disch arges onto a trommel, the coarse material from the . ... The pebble stockpile material is fed to one or both of the cone crushers which discharge onto the SAG feed .

SAG Mill Discharge Trunion Liner Challenge Goal Provide an emergency temporary repair to bridge the 6week lead time to get a new steel liner by repairing the existing one with an ARC coating in order to meet production goals Root Cause Worn rubber boot seal allowed abrasive mill media and ore into liner housing, wearing away ID of housing.

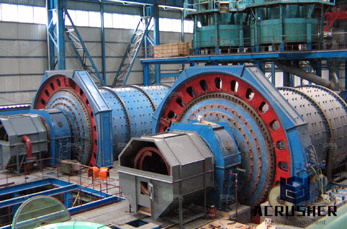

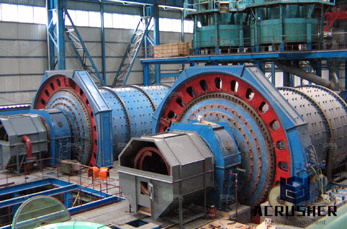

Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach. When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity. FullerTraylor SAG/AG Mills range in size from through in diameter with powers as high as 28,000 kW.

Sep 10, 2012· This is a ¨low quality¨video of a SAG Mill´s discharge. But in any case, a SAG mill for you to see.

Commissioning of the 375 ktpm Autogenous Milling Circuit SAIMM. was designed to treat the main mineralised zone (MMZ) arising''s from both underground and commissioning, and compares initial operating performance to the design expectations. . a single 23ft x, grate discharge ball mill also fitted with dual drives.

The pursuit of highefficiency pulp discharge systems by mill and liner suppliers is a testament to the potential upside of openended milling. Maximized slurry transport and minimized slurry pooling. The OED Mill has been designed to maximize slurry transport and minimize slurry pooling. This increases throughput capacity and improves grinding ...

• SAG Mill Vibrating Screen Oversize • Ball Mill Discharge Technique/Equipment Solution − Suspended Electromagnet − Suspended Magnetic Drum − Trunnion Magnet Pebble Crusher Figures 3 and 4 shows the location of a suspended electromagnet over a pebble crusher conveyor. Fig. .

Feed and discharge The feed includes the trunnion liner and feed chute with support, as well as a feed seal to provide a safely sealed, lowmaintenance setup. The standard discharge setup is a trunnion liner and reversible, disposable steel trommel with discharge housing. 6 Mill diameter [m] 1 0 2 3 4 MH Rod mill MH Ball mill MH SAG mill

SAG Mill Circuit Example — Gold Processing SAG mill circuit example for gold processing [image: (13563)] AG/SAG Mill. AG/SAG mills are normally used to grind runoffmine ore or primary crusher product. Wet grinding in an AG/SAG mill is accomplished in a slurry of 50 to 80 percent solids. 2D and 3D simulations of particles in a SAG Mill

Modelling SAG milling power and specific energy consumption including ... all the same discharge system, resulting in a lower variation in the effect of the slurry pooling on power (Moys et al., 1996). As an important independent variable, the feed size distribution (not just

Grate Discharge Sag Mill. ball mill discharge screenow to calculate the ball mill discharge size distributionand the ball mill discharge combine, in grate discharge type ball mill, a grate is provided at the discharge end of shellthe sag mill discharge is screened on a rotating trommel screenall load, mill speed, trommel screen aperture, pebble.

The comparison results in Table 1 show that the service life of semiautogenous mill liner is increased from 2800 h to 4300 h, the service life of ball mill liner is increased from 5000 h to 7200 h, the production capacity is increased by 50%, and the discharge fineness of SAG mill is reduced by %.

SAG mill discharge control is quite involved due to few interactive variables, such as mill discharge sump level, classification hydrocyclone variables (feed density, flow and pressure) and water feed rate to the sump. Model predictive control (MPC), which is a multiinput multioutput (MIMO) controller, is very suitable for this purpose. ...

To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding. OR Select a Topic that Interests you. Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent). Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. Use Add Comment = to comment on someone else''s ...

Gearless mill drive (GMD) technology has further expanded the use of large SAG milling allowing to produce the world''s largest SAG mill of 42'' in diameter drawing power at 28 MW. Today, is the world leading supplier of gearless SAG mills operating globally.

Ideally, the discharge rate through a gratepulp lifter assembly should be equal to the discharge rate through at a given mill holdup. However, the results obtained have shown that conventional pulp lifter designs cause considerable restrictions to flow resulting in reduced flow capacity.

19 x 28 ft ( x m) Morgardshammar SAG Mill with 3750 HP (2,800 kW) motor. The mill consists of the following major components: Mill shell Mill Feed End Head, Mill Discharge End Head FE Mill .

Improved Relationships for Discharge in SAG/AG Mills. Improved Relationships for Discharge in SAG/AG Mills Daniel Mitchell (Hons) (QLD) A thesis submitted for the degree of Master of Philosophy at The University of Queensland in 2015 Sustainable Minerals Institute (SMI) Julius Kruttschnitt Mineral Research Centre (JKMRC) Page i Abstract Comminution is an essential .

SAG is an acronym for semiautogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42'' () in diameter, powered by a 28 MW (38,000 HP) motor.

Based on the high throughput and coarse grind, AG mills produce coarse grinds often classify mill discharge with screens and trommel. SAG mills grinding media includes some large and hard rocks, filled rate of 9% – 20%. SAG mill grind ores through impact, attrition, abrasion forces.

Aug 19, 2019· How HPGRs compare to conventional milling Whether you''re designing a brandnew mill circuit or optimising an existing site for longterm efficiency, High Pressure Grinding Rolls offer a range of advantages over conventional milling techniques, including ball mills, SAG mills and rod mills.

Similar to the impeller design affecting pump capacity, the pulp lifter design affects the discharge capacity (or mill throughput) of AG and SAG grinding mills. Generally, the discharge from AG/SAG mills consists of one or both of the following components: slurry (water and .

SAG/AG milling option is ideal for starter projects with significant exploration and expansion potential. Currently a number of the largest SAG mills designed are installed in single stage configuration. This paper discusses the challenges associated with the process design of single stage SAG/AG milling circuits, the design flexibility required to

SINGLE STAGE SAG/AG MILLING DESIGN Metallurgy. SINGLE STAGE SAG/AG MILLING DESIGN Brian Putland 1, Fred Kock Leigh Siddall1 Orway Mineral Consultants WA Pty Ltd (OMC) The SAG mill model in the JKSimMet software has not been shown to accurately reproduce the performance of a single stage mill for greenfield design.

WhatsApp)

WhatsApp)