TCB Metals and Refining

Do you have value locked inside your ore concentrates? We can unlock that value and convert your ore into cash. TCB Metals and Refining, specializes in the recovery of precious metals from your ore .

WhatsApp)

WhatsApp)

Do you have value locked inside your ore concentrates? We can unlock that value and convert your ore into cash. TCB Metals and Refining, specializes in the recovery of precious metals from your ore .

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore ...

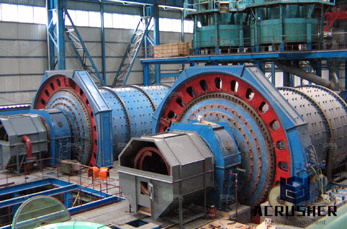

3,0005,000 TPD Iron Ore Process Plant 3,000 HP FLS Ball Mill, VTM 1500, 15 5deck Sizers, 6 SLon Outotec Magnetic Separators, Pumps, Northstar Disc Filter and Much More! Fleet of Mobile Equipment Available. VIEW MORE DETAILS LOCATED IN MINNESOTA USA

By 1907, the Calumet Arizona was the fourthmost productive copper mine in Arizona, and ran its own smelter in Douglas, Arizona. Their rich Irish Mag mine produced ore containing copper, lead, zinc, gold and silver. Another of their properties was the Junction Mine.

A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2. Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant. These figures are not a standard but reflect the nature of the ore and the design basis for a particular situation.

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of ...

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operation. This completely updated edition ...

Processing, smelting and refining gold. ... With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent in large tanks equipped with agitators.

Aug 06, 2015· We had a customer send us some very high grade gold quartz ore which we recovered troy ounces from only 300 lbs! We ran the quartz through our .

available for the extraction of gold metal from its ores. Amongst these methods, cyanidation is the most common method used in the leaching of gold from the ore. This process involves the dissolution of gold containing ores in dilute cyanide solution in the presence of lime and oxygen. For refractory ores such as

The copper mine and processing facility, formerly known as Casa Grande Mine and Lakeshore Mine, has been operated by several different companies since the 1880s. Open pit mining began in 1959 and underground mining began in 1970. Both oxide and sulfide ores were mined and processed.

Gold Processing Plants. Star Trace offers turnkey solutions for gold processing plants. Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of gold processing plant equipment. We specialize in gold processing plants, gold trommel plants and portable gold trommel plants.

Gold Processing Plant. 84 likes. We can bulid Gold ore processing Plant, which can process gold ore to gold bar, usually we use the Gold CIL / Gold CIP process, Maximize your profits.

Gold is usually found alone or alloyed with mercury or silver, but can also be found in ores such as calaverite, sylvanite, nagyagite, petzite and krennerite. Most gold ore now comes from either open pit or underground mines. The ores sometimes contain as little as 5/100 of an ounce of gold .

Gold ore processing plant includes different types of process namely: ... Smelting; Gold ore processing plants should be started with the feeder and it will take the extracted materials uniformly to the crusher for the first process. This process is used for resize and pulverize the gold ores into smaller than particles. For secondary crushing ...

20+ items· 21 Gold Ores Processing Companies in the United States. Search or browse our list of Gold Ores Processing companies by category or location. ... Manta has 21 companies under Gold Ores Processing in the United States. ... Modular Gold Plants gold ores processing gold ores processing. Specialists in Advanced Gold Processing and Water Treatment ...

USED 3,0003,500 TPD GOLD PROCESSING PLANT, including Grinding Circuit, CIL System Tanks, Gold Assay Lab, Truck Shop, Buildings, Warehouse Spare Parts and More. ... USED 300500 TPD Modular Gold Plant including Jaw Crusher, Impact Crusher, 6'' x 8'' Ball Mill, Falcon Concentrators, Screens, Pumps, Conveyors, Cyclones and More.

Recent developments in dry washing equipment have made it possible for a one or twoman operation to work larger volumes of dry placer ground without water, and obtain good results in gold recovery. Dry processing recovery systems generally use air flows to do .

Todate we have completed over 30 heap leach designs including locations such as Alaska, Arizona, Nevada, Mexico, Arizona, Turkey, Armenia, Ghana, Chile and Peru. Bioleaching – experience designing, constructing and operating bioleach systems including plants in Chile, Brazil and Africa for refractory gold, copper, zinc and cobalt.

However, in 2005, the company announced the goead for a 210m project to create the world''s first commercial copperconcentrate leaching / direct electrowinning operation at Morenci, a proprietary technology that allows primary sulphide ore treatment by leaching in combination with secondary ore processing.

Para Resources Inc. owns 88% of its subsidiary Gold Road Mining Corp. Para acquired the mine, patented claims, a 500ton/day CIP mill and an oreprocessing facility, built on private land in 1995, including all rolling stock, vehicles, laboratory and other assets for 7 million.

arizona gold ore processing facility. Find the Right and the Top Arizona gold ore processing facility for your coal handling plant . D S Mine Development LLC, Arizona, Gold Ore.

TCB International LLC is a Phoenix, Arizona based company specializing in the processing of precious metal ores.. Our state of the art plant contains an in house laboratory and leaching facility. As each ore has its own unique properties, our laboratory and experienced team allows us to work with your ore from start to finish to maximize your ores'' precious metal recovery.

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of % pure copper called cathodes, which will ultimately be made into products for everyday most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different ...

WhatsApp)

WhatsApp)