QINGDAO AOKTEC IMPORT EXPORT CO., LTD.

ALUIMINA GRINDING BALL_Mill Bricks Liner_INERT PACKING BALL_ALUMINA LINING_MISAIC TILES_IWearResistance BeadsQINGDAO AOKTEC IMPORT EXPORT CO., LTD.

WhatsApp)

WhatsApp)

ALUIMINA GRINDING BALL_Mill Bricks Liner_INERT PACKING BALL_ALUMINA LINING_MISAIC TILES_IWearResistance BeadsQINGDAO AOKTEC IMPORT EXPORT CO., LTD.

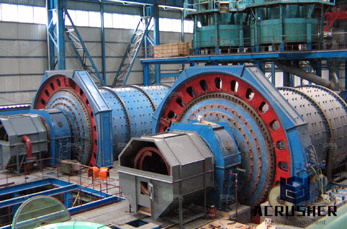

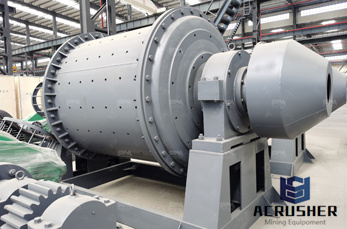

Ball mill is an efficient tool for grinding many materials into fine powder. The ball mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in building material, chemical industry, etc.

CHAENG cement ball mill equipment can reduce energy consumption by 30% and increase the processing amount by 1520% after transformation. The cement ball mill can perform dry process production and also wet process production, moreover it can do grinding and drying at the same time.

Reliable and effective grinding mills includes being safe throughout. When the mills are quoted we make sure to include any and all safety components needed. Long life and minimum maintenance. To help you get the most of your business, we have designed our ball mills with longterm operation in mind with a minimum need for maintenance.

The purpose of the training is to Identify and understands necessary known and unknown information towards the completed cycle of the grinding system, whether is a ball or vertical mill. Throughout the course the lectures are supplemented with exercises and case studies, allowing the participants to relate the course material to their cement grinding facility and as a result understanding the ...

Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with...

The segmentation of grinding and milling systems. Module 2 – Ball mills. This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process. * Mechanical description of the different types of mills. * Ball mill grinding equations and dimensioning. * Mill internals, media, liners and ...

The Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a unique combination of theory and practical work section applied to the maintenance inspection of the ball mill system. This course offers an indepth understanding of the maintenance activities, providing the precise tools to achieve optimal levels of personal performance and ...

daily preventive maintenance on cnc mills. daily preventive maintenance on cnc mills – Grinding Mill The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. Lathe Preventative maintenance check list sheet for yearly and monthly pm''s for .

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

Our Motivation. We are constantly developing and want to become even better and more efficient. In order to continue to be a partner to our customers over the long term, we want to share all the knowledge we have gained from various projects and our own development: Christian Pfeiffer invites its customers each year to a fourday seminar in Beckum on this topic.

ball mills maintenance program . Automatic Combined Rice Mill Modern Mini Rice Mill Plant For Sale, Find easy operation, convenient Maintenance, big output, high rice precision and it is a new According to the design program equipped with the right machine and provide installation, operation training. ball mill raw rice mill plant laboratory ball mill.

We offer autogenous (AG), semiautogenous (SAG), ball, rod, and pebble mills in sizes ranging from kWs up to 30+ MW. Our product range also includes a number of unique solutions, including the world''s largest acidresistant grinding mills, which can operate with extremely corrosive slurry.

Aug 20, 2014· The mill''s cylindrical chamber contains a grinding medium (it might be flint pebbles, or ceramic, rubber, chrome or stainless steel balls) which grind material down into a fine powder as the chamber is rotated at speed. ... Typical Ball Mill Maintenance Typically, operations that use a ball mill face a maintenance schedule that incorporates 3 ...

Ball Mill Maintenance Shop and Field work. Ball mill maintenance our shop and field crews make a unique combination to provide complete and up to date ball mill maintenance services. The shop is fully equipped with the large machining, fabrication, and engineering capabilities to rebuild your mill .

Ball mill preventive maintenance (PM) It is a frequency work to maintain and repair ball mills, AG mills and SAG mills. The maintenance work influences the rotational speed and service life of ball mills. In order to reduce downtime of ball mill, regular examination and .

Jan 12, 2015· 1 2. Mill Reline Maintenance. General Mill Maintenance. Grinding Circuit Maintenance. Workforce South Pacific Limited (WFSP) has been professionally maintaining SAGBall mills .

Wide Application of Ball Mill Ball mill, as the key grinding equipment of the materials, is widely used for mineral grinding such as cement, lime, quartz, slag, silica, iron ore, copper ore, gold ore, bauxite, calcite, barite, gypsum and other minerals in mining, quarry, chemical, cement and other industries.. Ball mill is the necessary equipment in ore beneficiation plant.

Grinding Mills Maintenance | Crusher Mills, Cone . Raymond mill should take good repair and maintenance so that our Raymond mill can run in good condition during grinding industry and mining industry. Vertical Mill and Ball Mill Maintenance Course Grinding of raw materials, coal and cement clinker is a vital function and involves three major ...

mills grinding supplier Botswana DBM Crushergrinding mill maintenance schedule botswana. ... T130X Super fine grinding mill, HGM Micro powder grinding mill, TGM Trapezium grinding mill, Hammer mill and Ball mill, which can be used for Processing Limestone, Quartz, Calcite, Gypsum, Dolomite, Barite, Talc, Coal, Calcium Carbonate, Slag, Iron ...

The ball mill is the most important equipment in the beneficiation equipment, and the structure is reasonable and price concessions. Dry grinding and wet grinding are all possible, and the fineness is about 800 mesh, which can be adjusted.

They can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill and some or all of the work done by a ball mill. SAG mills are also an optimum solution for wet grinding since crushing and screening in these cases can be difficult, if not impossible. Efficiency through automatic operation

grinding ball mill maintenance program Crusher MachineHome About Us Products Mining Grinding Contact UsHydraulicdriven track mobile plant Mobile crushing makes your mining business much easier and more efficient...

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

WhatsApp)

WhatsApp)