The world''s highest grade gold mines

Jul 16, 2015· Barrick/Newmont JV''s Turquoise Ridge underground gold mine complex. Source: Panoramio. The grade or concentration of a mineral or metal in ore .

WhatsApp)

WhatsApp)

Jul 16, 2015· Barrick/Newmont JV''s Turquoise Ridge underground gold mine complex. Source: Panoramio. The grade or concentration of a mineral or metal in ore .

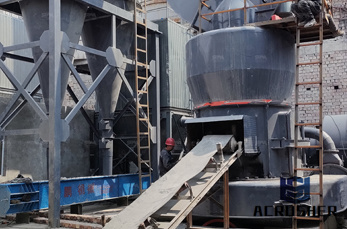

At the Gold ore Processing Plant, gols should be extracted from the ore. The processing plant alternates between treating ore from the mine open pit and from the underground mine. GMC Machinery is one. Gold ore concentration plant

Gold ore concentration plants. At the Gold ore Processing Plant, gold and silver are extracted from the ore. The processing plant alternates between treating ore from the Martha Mine open pit and from the Favona underground mine. Gold ore concentration plants consists of the following stages:

Gravity concentration is the separation of minerals based on differences in specific gravity. A gravity concentration process is designed to recover very high grades of valuable ore material into very small masses. The resurgence of gravity concentration in mining has come about due to its simplicity and low environmental impact.

In case of mineral processing concentration means the increase of the percentage of the valuable mineral in the concentrate. ... gold, copper, coal and diamonds. Dewatering ... The water extracted from the ore by dewatering is recirculated for plant operations after being sent to a water treatment plant.

Froth flotation is a process for selectively separating hydrophobic materials from is used in mineral processing, paper recycling and wastewater treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century.

Sep 23, 2019· Not only in the gold ore concentrate/separator plant, but also in other ore concentration plant like for iron ore, zinc ore, copper ore, etc. Production Capacity: 10280TPH. Configuration : Jaw crusher, impact crusher, hammer crusher, flotation machine, classifier, ball mill, concentrator, etc.

Gold ore mining and processing plant « Crusher Parts. The finer particles obtain more grinding in the ball mill, and are size classified to give your final item of 80% Gold ore concentration plant .

Gold ore concentration process. The Crushing Sections: The gold ore from the mine site is always with size 0400mm or 0600mm after blasting. We use the crushing plant to crush the raw gold ore .

Bauxite mine is actually kind of ore minerals collectively formed mainly by gibbsite, a boehmite or a diaspore which can. Bauxite processing plant Copper ore a valuable mineral source for all countries.

We have gold ore concentration plant for beneficiation,The practice of gold minerals beneficiation is optimized by using the information obtained from applied mineralogy In this way at the moment of development and select a process for treatment a gold ore try to identify the gold .

Free Gold Recovery. After crushing ore clumps to a manageable size of 20mm or less, via the Python or other crushing circuit, Gekko offers a range of free gold recovery options.. At the coarse 350 micron 20mm ore size, a preconcentration jigging circuit can be designed incorporating a proven, efficient recovery device for free gold: the InLine Pressure Jig.

The processing plant alternates between treating ore from the mine open pit and from the underground mine. HOC Machinery is one of world leading suppliers of complete gold ore concentration plant. Gold ore concentration equipment. In gold concentration, high technology gold mining equipment, such as gold detectors, elegant modern dredges, and ...

Copper Ore Crushing Plant in Chile. HT Machine set up a local branch office in Chile, which is one of the most important sales markets of HT Machine in South America. Each year, a large number of clients purchased crushing and powdermaking.

Gold ore concentration plant 24 Comments. Gold Flotation Process is use to process fine gold, sulfide goldcontaining quartz ore . Concentration of gold flotation process. Flotation for large density and coarse particle . Limestone Processing Plant 24 Comments. Dolomite stone processing plant. Dolomite is kind of carbonate mineral which ...

May 24, 2014· This is a test run of a pilot plant for recovering fine gold from hard rock ores. After crushing and milling the slurry is pumped over a scalping screen which also mixes the pulp density of the ...

gold ore gravity concentration plant for small scale miners · usage in the gold ore beneficiation plant Reina de Oro, located in the town of Vetas . environmental impact of small scale gold mining and maintain local sustainability. . of water are found in the stages of milling and gravity concentrations.

gold ore concentration plants grinvich. gold ore concentration plant galgotiasbschool. gold ore concentration plant. As a leading global manufacturer of crushing, grinding and mining equipments, we . Get Price And Support Online; gold concentration machine in ore processing plant. Gold mining equipment, processing plant,crushing machine .

Various methods such as gravity concentration, flotation, panning, pyrometallurgy, cyanidation etc are available for the extraction of gold metal from its ores. Amongst these methods, cyanidation is the most common method used in the leaching of gold from the ore. This process involves the dissolution of gold

Gold ore concentration plant. At the Gold ore Processing Plant, gols should be extracted from the ore. The processing plant alternates between treating ore from the mine open pit and from the underground mine. Imara Machinery Machinery is one of world leading suppliers of complete gold ore concentration plant.

GOLD FLOTATION The flotation process, which is today so extensively used for the concentration of basemetal sulphide ores and is finding increased use in many other fields. In 1932 flotation plants began to be installed for the treatment of gold and silver ores as a .

The object of gravity concentration is the separation of the heavy valuable mineral from the light worthless gangue. Complications are often introduced by the fact that various base minerals must be separated from one another, an ore being subdivided into several products. Most gold ores, however, only require separation into two parts—the "concentrates," in which the precious metal is ...

The simultaneous leach and absorption phases of the CIL process were developed for processing gold ores that contain pregrobbing materials such as natural absorptive carbon. These reduce the gold yield by attracting gold meant for the activated carbon. Simultaneous leaching .

The concentration of Ore can define as the chemical process of eliminating impurities like sand, rocks, silt, grit etc. from the ore for the extraction of metal. In this content definition and methods for the concentration of ore are explained along with the definition of ore and its types.

WhatsApp)

WhatsApp)