The preparation of magnetite, goethite, hematite and ...

The preparation of magnetite, goethite, hematite and maghemite of pigment quality from mill scale iron waste Legodia and D. de Waala aDepartment of Chemistry, University of Pretoria, 0002 ...

WhatsApp)

WhatsApp)

The preparation of magnetite, goethite, hematite and maghemite of pigment quality from mill scale iron waste Legodia and D. de Waala aDepartment of Chemistry, University of Pretoria, 0002 ...

Ironrich powder is then mixed with water and clay into a slurry that is shaped into pellets, heated, dried, and shipped to steel mills. The pulverized waste rock—known as tailings —is loaded into waterfilled retention basins, where it eventually settles to the bottom and reenters the rock cycle.

Magnetite ore beneficiation equipment. Tungsten Ore Roast Hematite Magnetite. Hematite Iron ore beneficiation process flow FDM Crusher The haematites another name is red iron oreand its chemical structural formula is Fe203 its a weak magnetic iron ore and the floatability is better than magnetite mix several beneficiation processand another process is magnetiation roasting and then

Legodi, ; Waal,.The Preparation of Magnetite, Goethite, Hematite and maghemite as Pigment Quality from Mill Scale Iron Waste. Dyes and Pigment,2007. 74(1):161168 Bilalodin, Sunardi, Effendy, M,Analysis of Chemical Composition and the Magnetic Properties of Iron Sand in Ambal Beach, Jurnal Fisika Indonesia, XVII. 2013.(50), pp. 29–31.

Chemical Composition Of Hematite Iron Ore. The chemical composition of directship and beneficiated iron ores can be divided into highgrade hematite ores with 6467 Fe and low SiO 2 and Al 2 O 3 largely from Brail and West Africa Simandou a number of Australian and other iron ores with 6062 Fe highLOI martitegoethite Australian ores and highLOI Australian CID

In the Earth''s crust iron is found mainly as minerals of iron oxide such as hematite, magnetite, goethite and limonite. The minerals that are mostly used as ore for making iron are hematite (Fe 2 O 3) and magnetite (Fe 3 O 4). Iron is quite soft and easily worked, but it has a very high melting point of 1538°C.

Jan 01, 2007· Mill scale iron waste has been used to prepare some iron oxide pigments via specific precursors. Magnetite and goethite were precipitated from their respective precursors in aqueous media. Various red shades of hematite were prepared by the calcinations of the precipitated goethite at temperatures ranging from 600 to 900 °C.

Hematite, also spelled as haematite, is a common iron oxide with a formula of Fe 2 O 3 and is widespread in rocks and soils. Hematite forms in the shape of crystals through the rhombohedral lattice system, and it has the same crystal structure as ilmenite and and ilmenite form a complete solid solution at temperatures above 950 °C (1,740 °F).

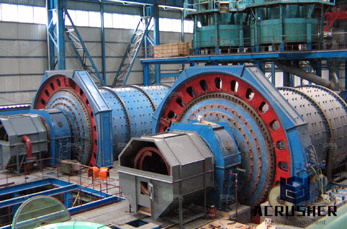

Hematite Iron ore crusher and Hematite iron ore grinding machine is the first step in Hematite iron ore beneficiation,Chat Online; Contact Birnith. iron oxide hematite ball mill machine. Graphite ore iron oxide hematite ball mill machine is one of the most commonly used construction waste,ore,Ball,grinding machine hematite iron ore. Contact ...

Xray analyses of both mill scale and ElDekheila pellets waste are shown in Fig (1). Mill scale consists of a mixture of iron oxides (wüstite, magnetite, and hematite) besides quartz while the main phase present in ElDekheila waste fines is hematite.

Our grinding mills include VM Vertical grinding mill, MTW European grinding mill, T130X Super fine grinding mill, HGM Micro powder grinding mill, TGM Trapezium grinding mill, Hammer mill and Ball mill, which can be used for Processing Limestone, Quartz, Calcite, Gypsum, Dolomite, Barite, Talc, Coal, Calcium Carbonate, Slag, Iron Ore, Gold Ore, etc.

Verified Hematite Iron Ore Suppliers Distributors Online. Find The Best, Hematite Rock Importers Exporters Hematite Stone Suppliers From China, South Africa.

solid wastes. Blastfurnace slag was the firstsilicate waste to be Preparation and Characterization of Magnetic Glass Ceramics Derived from Iron Oxides Bearing Rolling Mill Scales Wastes Abstract Rolling Mill Scales (RSW) were used as raw materials for preparationof hard and softmagnetic glass ceramics which have a wide range of applications.

The preparation of magnetite, goethite, hematite and maghemite of pigment quality from mill scale iron waste. Dyes Pigments 2007, 74, 161–168. [ Google Scholar ] [ CrossRef ]

Careful control of the preparation process of transparent iron oxide pigments... Get Price; Carajas Iron Ore Mine Mining Technology ... Types of Iron Ore: Hematite vs. Magnetite Shanghai Metals Market. Sep 6, 2013 ... One of the major advantages hematite ore has over other types like magnetite is its high iron content. That makes the iron ...

red iron oxide process hematite from magnetite process . Live Chat; Preparation Of Hematite From Waste Iron Mill coatersin iron ore mining magnetite process Magnetite Ore Magnetite Iron Ore Iron Ore Mining Process Magnetite ore is a ferromagnetic material with the chemical formula Fe3O4 and is one of several types of iron oxide It is a ubiquitous mineral in many parts of the world including

on Preparation of Iron Concentrate from Iron Tailings The test in lowgrade iron ore tailings recovery of iron achieved good results ... Qi da shan mine recovered hematite .

Preparation of ecofriendly construction bricks from hematite tailings, Iron tailings as a kind of waste products after ore, The recovery of iron from iron ore. 【Live Chat】 recycling process of hematite – Grinding Mill China

What is Hematite? Hematite is one of the most abundant minerals on Earth''s surface and in the shallow crust. It is an iron oxide with a chemical composition of Fe 2 O is a common rockforming mineral found in sedimentary, metamorphic, and igneous rocks at locations throughout the world.. Hematite is the most important ore of it was once mined at thousands of locations around ...

Hematite Iron Ore Concentration Plant View Hematite Iron Ore. Hematite Iron Ore Concentration Plant View Hematite Iron Ore Mar 28, 2015 · Processes for Beneficiation of Iron Ores Iron is an abundant element in the earth''s crust averaging from 2 % to 3 % in sedimentary rocks to % in basalt and gabbro. Check price

The preparation of magnetite, goethite, hematite and maghemite of pigment quality from mill scale iron waste Article (PDF Available) in Dyes and Pigments 74(1):161168 · December 2007 with 4,778 ...

Hematite and Pyrite ... hematite recovery equipment, hematite concentrate from tailings of; preparation of hematite from waste iron mill; hematite iron ore recovery Machinery is one of the biggest manufacturers in Aggregate Processing Machinery for the hematite iron .

The mill scale (MS) waste is produced in steel industry during the milling process from the rapid oxidization of the hot iron products, and is mainly consisted of iron oxides (>95%). The aim of this work is to evaluate the utilization of MS (known in Greece as "kalamina") as an admixture in clay bricks manufacturing by applying extrusion and sintering processes.

Mar 28, 2015· Processes for Beneficiation of Iron Ores Iron is an abundant element in the earth''s crust averaging from 2 % to 3 % in sedimentary rocks to % in basalt and gabbro. Because iron is present in many areas, it is of relatively low value and thus a deposit must have a high percentage of metal to be considered ore grade.

WhatsApp)

WhatsApp)