manufacturing process of the cement YouTube

Jul 17, 2020· this video is regadring the manufacturing process of the cement. please wach it till the end and i am sure you got full information of manufacturing process of cement.

WhatsApp)

WhatsApp)

Jul 17, 2020· this video is regadring the manufacturing process of the cement. please wach it till the end and i am sure you got full information of manufacturing process of cement.

Dry Process for Manufacturing of Cement. Materials. Jun 22, 2016 Ritesh Patel . Ritesh Patel. Mr. Ritesh Patel is a Civil Engineer who has earned Bachelor''s degree in 2005. He is a senior editor at .

Methods of cement manufacturing 1 Wet process ___ grinding and mixing of the raw materials in the existence of water. 2 Dry process ___ grinding and mixing of the raw materials in their dry state. The process to be chosen, depend onthe nature of the used raw materials.

Aug 28, 2018· Cement Manufacturing Process. Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the .

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln.

There are two different processes for manufacturing cement. wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are dry ground to form a powderlike substance. Both the processes are in use and have their own advantages and disadvantages.

At cement plant, according to different raw materials preparation methods, cement manufacturing can be divided into the dry process (including semidry process) and wet process (including semiwet process). Next, we will discuss the wet process of cement manufacturing in details.

A clean and revolutionary cold manufacturing process. Hoffmann Green has initiated a technological breakthrough based on changing the composition of cement so that it does not contain clinker, the main source of CO2 emissions in traditional cement production, as well as creating a cold and clean cement manufacturing process (no firing of raw materials).

The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water. The wet process of cement manufacturing too popular for several decades because of the possibility of more accurate control while raw material mixing.

Manufacturing Process At AfriSam we take pride in ensuring that the cement we produce is of the highest quality. Get a glimpse into the cement manufacturing process here.

is a platform for academics to share research papers.

May 12, 2020· The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine grinding. Some of the main ingredients used to make cement include limestone, clay, shale, iron, and sand.

Process of Manufacturing of Cement The cement is manufactured by integrating the calcareous component and argillaceous component in a ratio of 3:1. The calcareous component can be limestone, chalk, marine shells, marl whereas argillaceous components can be shale, clay, blast furnace slag, slate.

The Process for Making Portland Cement Materials that contain appropriate amounts of calcium compounds, silica, alumina and iron oxide are crushed and screened and placed in a rotating cement kiln. Ingredients used in this process .

Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process. The two processes are essentially alike except in the wet process, the raw materials are ground with water before being fed into the kiln.

Aug 28, 2018· Cement Manufacturing Process. Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix.

Aug 30, 2012· Cement Manufacturing Process Phase IV: Kiln Phase Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 ⁰C. This temperature begins a chemical reaction so called decarbonation.

Cement manufacturing process . The quarry. Cement plants are usually located closely either to hot spots in the market or to areas with . sufficient quantities of raw materials.

Methods of Manufacturing Process of Cement. At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process. The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry state.

Manufacturing cement at the Lafarge Seattle plant is by a "wet process". As a result, raw materials are mixed with 30 to 40% water during grinding to form well mixed slurry. This wet process is .

The definitive resource on all aspects of cement manufacturing addresses the current issues facing the industry. This twovolume, limited edition is a must have reference for personnel involved in the cement industry including production, quality assurance, process .

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement .

The resulting cement slurry flows into storage tanks. Must Read: Dry Process For Manufacturing of Cement When lime stone is used, first blast it, then crushed in two progressively smaller crushers and then fed into a ball mill with the clay dispersed in water.

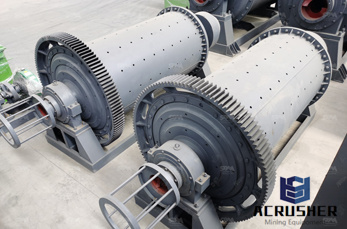

Cement grinding. The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement. Commonly used separators are in closed circuit grinding are: O –sepa, Sepol and Sepax separators to achieve a finish cement .

WhatsApp)

WhatsApp)