EPA Tightens Emissions Rules for Coal Processing ...

The Environmental Protection Agency has adopted final rules tightening emissions limits for coal preparation and processing plants and imposing new reporting requirements on those facilities.

WhatsApp)

WhatsApp)

The Environmental Protection Agency has adopted final rules tightening emissions limits for coal preparation and processing plants and imposing new reporting requirements on those facilities.

Coal preparation. As explained above, during the formation of coal and subsequent geologic activities, a coal seam may acquire mineral matter, veins of clay, bands of rock, and igneous addition, during the process of mining, a portion of the roof and floor material may be taken along with the coal seam in order to create adequate working height for the equipment and miners.

Coal preparation is an important aspect of coal handling. When coal leaves a plant''s coal handling system, it generally is sent to one of two places. Depending on the design of the plant, the coal may go directly to a boiler furnace to be burned, or it may go through coal processing equipment, such as a pulveriser, before it is burned.

Since the merger of Advitech Pty Limited and Shaw Engineering in 2011, Advitech has been providing effective solutions for coal preparation plant (CPP) upgrades and coalspecific materials handling solutions throughout the Hunter Valley and beyond.

Coal Prep Technology Pty Ltd is based in the heart of the Hunter Valley, NSW offering consulting services to the mining industry specialising in the management and the optimisation of coal processing facilities Our mission is to identify, justify and manage the implementation of investment pathways to achieve the optimum processing plant performance for a Client determined .

Coal preparation is an important aspect of coal handling. When coal leaves a plant''s coal handling system, it generally is sent to one of two places. Depending on the design of the plant, the coal may go directly to a boiler furnace to be burned, or it may go through coal processing equipment, such as a pulverizer, before it is burned.

On September 25, 2009, the Environmental Protection Agency (EPA) revised emissions control requirements for new coal preparation and processing plants. Those new performance standards were designed to further reduce emissions at new coal preparation and processing plants that process more than 200 tons of coal per day.

Coal Preparation. Parnaby Cyclones with over 50 years of experience is a key partner in maximizing the efficiency of coal preparation. Systems have been developed for washing and separating different grades of coal, the recovery of fine coal particles and the treatment and disposal of effluent.

mining prep plant equipment Mineral Processing EPC. Filter Press Feed Pump,Coal Prep Plant Pump,Lime Slurry Pump . Filter Press Feed Pump,Coal Prep Plant Pump,Lime Slurry Pump, Find Complete . and supplier of slurry pumps and complete sets of equipment; Muyuan Pump . meet the requirements of global mining. Learn More

• EPA estimates that 22 new coal preparation and processing plants consisting of coalhandling equipment (, coal processing and conveying equipment, coal storage systems, coal transfer and loading systems, and open storage piles) will be built over the next five years and would be subject to these revised standards.

Equipment needed for coal wash processing. The equipment and process of the coal washing plant are related. The three most basic processes of the coal wash plant are the preparation work before the sorting (crushing, screening, grading), the sorting operation, and the processing .

Nov 05, 2019· Most of the time, a coal preparation plant will have a method of storing or purifying this water, often through evaporation. The dangerous material is a common point of discussion when talking about the dangers of coal mining processes. Most of the time, a coal preparation plant will keep a stockpile of coal ready for processing.

With coal preparation, raw coal is cleaned using different physical processes, with or without any chemical reagents, to get a product which can be sold in the market. Coal preparation process starts with crushing and screening of freshly mined coal, which removes some of the noncoal material.

What Is Coal Preparation? • Coal preparation is the removal of undesirable material from the RunofMine (ROM) coal by employing separation processes which are able to differentiate between the physical and surface properties of the coal and the impurities. Through coal preparation.

Coal Processing Plants: Star Trace offers turnkey solutions for coal processing plants. We are one of the leading project suppliers for zircon plants and we work closely with our customers to fulfill their specific needs for a customized packaged solution. Specialized in the .

The more details you give on your situation, the better we can help you. Leave your phone number if you would like us to call you.

The United States currently operates 268 coal preparation plants in 14 states according to the latest annual census of coal processing plants conducted by Coal Age . The facilities, which are primarily located in West ia (80), Kentucky (56), and Pennsylvania (44), represent a total installed feed capacity of over 200,000 tons per hour.

the inspector in understanding the coal preparation process and the effects of operating parameters on process emissions. Background information on the coal preparation industry is presented in Section, which describes the purpose of coal preparation, and the geographic location of plants.

Modern Coal Related Technology ... Safety Related Equipment: End Uses of Coal: Coal Preparation. A Coal Preparation Plant (CPP) is a facility that washes coal of soil and rock, preparing it for transport to market. Coal Preparation Plant is located in Whitley County Kentucky.

The Coal Preparation Society of America (CPSA) brings the latest in coal processing technology expertise, equipment and networking events to the Lexington Convention Center. Now as a biannual event, the coal prep industry returns to the city equidistant between the Illinois Basin and the Appalachian coal fields.

to visualize a multicircuit preparation plant processing coal from several sources for different end uses. In fact, Squires(l) envisages by the late 1980''s, when the technology becomes available, a COALPLEX plant which is able to produce electricity, gasoline, coal gas and char as its products.

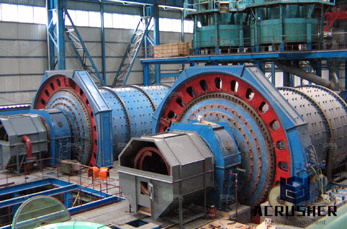

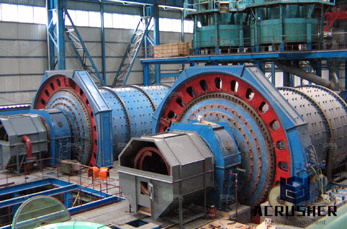

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

We have the ability to provide superior solutions through our global knowledge of the coal industry combined with our strength and expertise in the minerals processing industry. Our aim is to deliver superior coal process solutions for our clients big or small, regardless of the location.

The Basic Course in Coal Preparation will provide you with a comprehensive theoretical and practical introduction to the coal preparation process as implemented on coal processing plants. The course focuses on the critical issues of geology, market demand, sampling and analysis, sizing and reduction, common coal preparation processes, solid ...

WhatsApp)

WhatsApp)